PCS

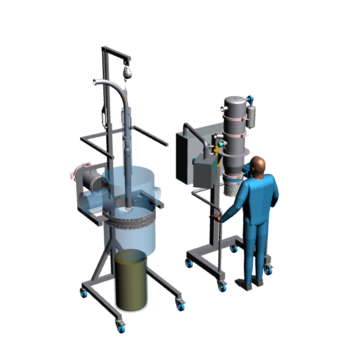

Combining the benefits of flexible technology with vacuum conveying, the module PCS from ILC Dover/Jetsolutions reduces process time for transfers and significantly improves operators ergonomics.

With the capability to meet a Containment Performance Target of less than 1.0 µg/m³ on a TWA or to simply contain for a dust free transfer the PCS makes processing easier and faster than conventional transfer systems.

- Drums can be docked with the lid on to assure high containment

- Typical time for docking a drum is less than 5 minutes reducing the time from conventional systems by half or more

- The open work space created by the “Flexi” improves the operator ability to use the pick-up wand and see into the drum improving ergonomics

- Fully automated PCS design conveys powders to the receiver and efficiently releases the powder from the process gas into your process

Advantages:

- Low footprint

- Able to transfer a wide range of products (fine, non-free flowing, hygroscopic, sticky powders)

- Transfer capacity from few kg to 4 ton per hour

- Safe conveying of API/HAPI’s - up to OEB5

- Integrated hi efficiency in-line filter cleaning system

- Low air purge during the product discharge

- No tools required for disassembling the system

- Easy to clean or CIP

- cGMP and Eex. compliant

- Docking the drum to the PCS, using a connecting stretch liner

- Take off the drum’s lid, using the gloves

- Creation of permanent under-pressure inside the PCS

- Powder suction

- PCS filling until reach the HLS

- Product discharge and filter cleaning

- After transfer the product, the lid can be positioned again on the drum

- Crimp the connecting liner and dispose the empty drum

Actualités

no news in this list.

Expos-Conférences

no news in this list.

Liens Rapides

- Actualités

- Expos-Conférences

- Newsletters

- Documentation